Counterfeit fashion products are costing in terms of brand reputation and revenue and laser marking technology could be the answer.

The Italian Patents and Trademark Office estimates that in the eyewear industry alone, counterfeiting causes a loss of approximately 15% of the market (equating to €75-100 million in sales lost by Italian companies and 500 fewer employees each year).

Sunglasses are Category One “personal protective equipment” (PPE), used to protect the eyes against the sun’s rays. They are regulated by a European Directive (89/686/EC), which guarantees the essential safety requirements, which counterfeit glasses cannot meet. The lens protects the eye against harmful solar radiation (UV and violet-blue rays). The frame must be made from non-toxic materials which do not irritate the skin (by causing contact dermatitis for example).

Sisma developed two different approaches for trademark protection by exploiting the laser possibilities: nanoscribing and hologram creation.

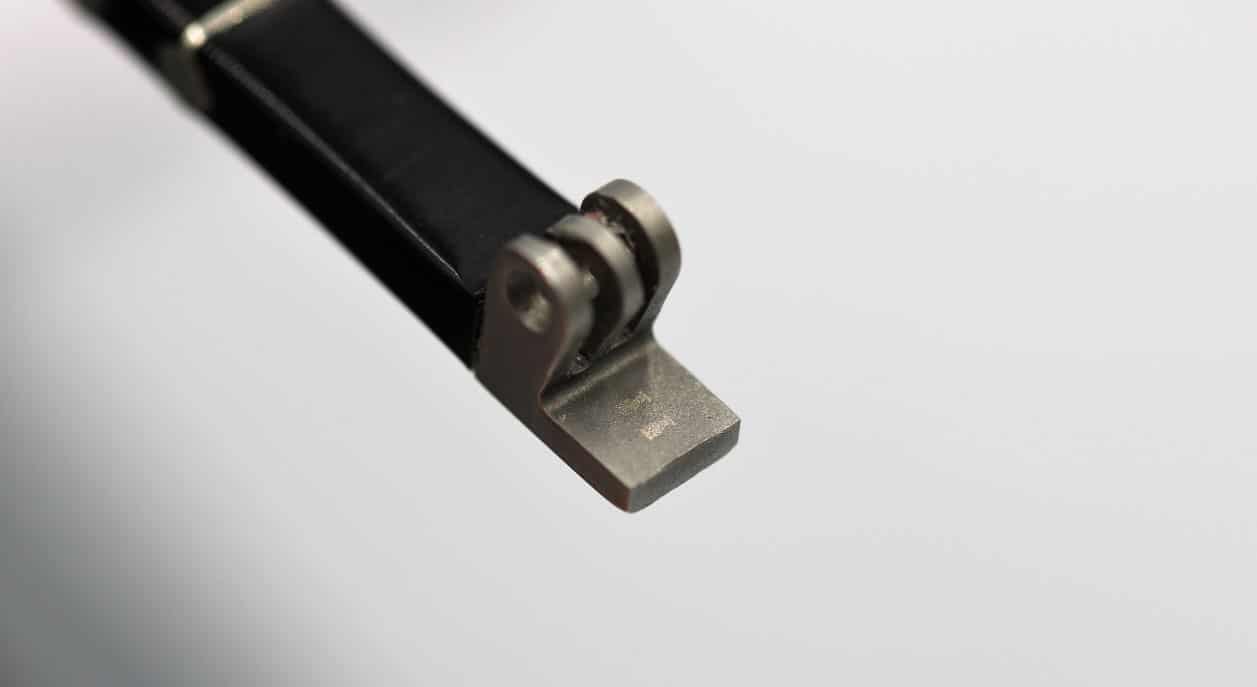

Micromarks

One appealing strategy is to add microfeatures to the surface of the item being protected. These features can be human-readable in the form of alphanumeric characters, or machine readable in the form of simple micro-2D codes (data matrices or QR codes) or more sophisticated encrypted microcodes. The size of these structures has to be on the scale of micrometres or smaller.

We consider features that can be visualised through cheap optical devices such as small microscopes or powerful eyeglasses. Codes of smaller dimensions (in the nanoscale range) would need very expensive ‘printing’ and detection techniques to realise.

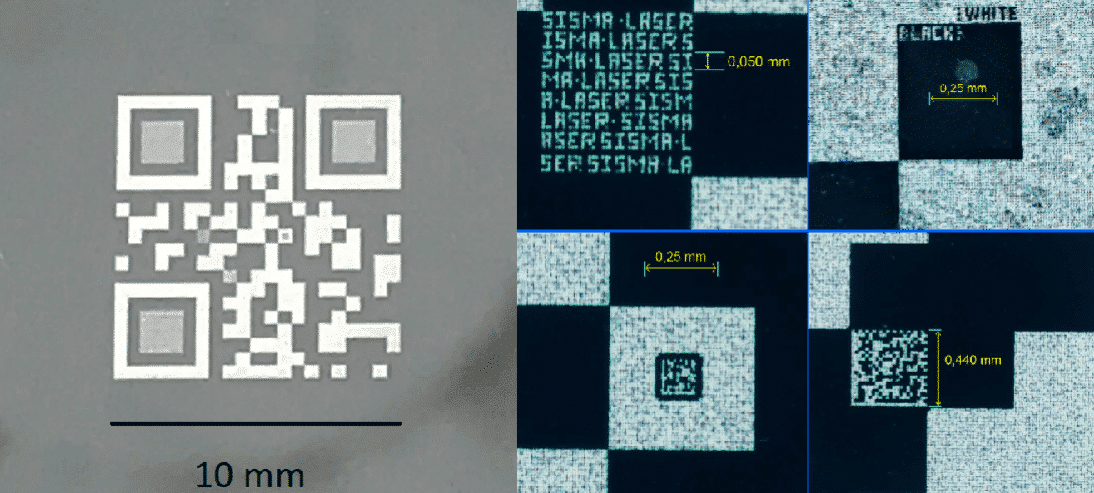

Figure 1 – Left: QR code marked with a UV nanosecond pulsed laser on a polished stainless steel. Right: Magnified view of the hidden microfeatures inside the QR code.

On polished stainless steel, a standard QR code (see figure 1) has been marked with an UV laser. The unicity of the 2D code is strengthened by replacing some pixels, or part of them, with microtexts or other microDM codes. Whereas the QR code is easily readable by a mobile camera, all hidden information requires some means of magnification to be spotted and decrypted.

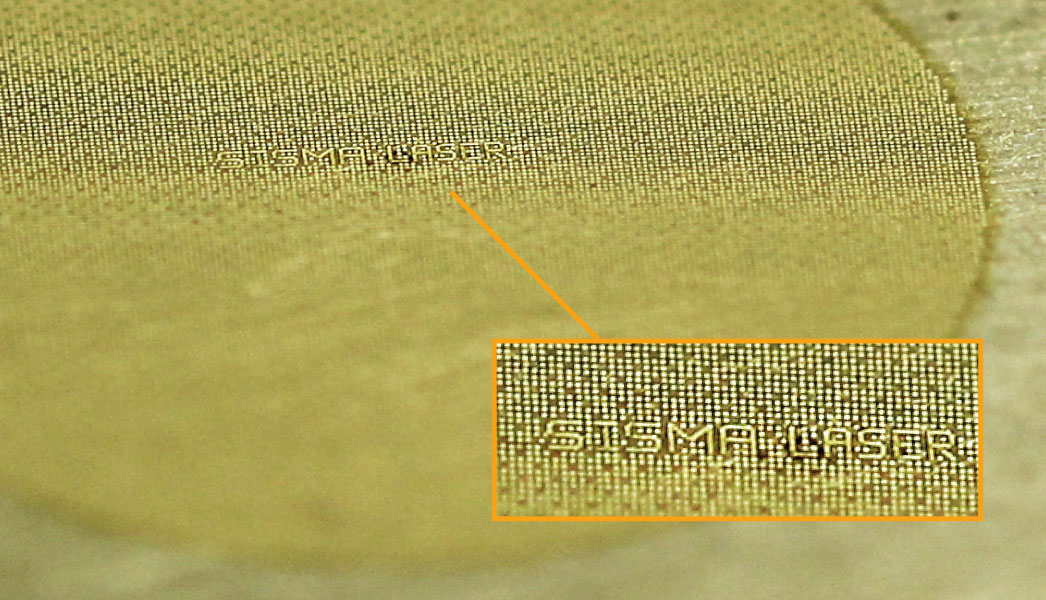

Microfeatures can be hidden within any standard marking or engraving patterns such as photos, textures or vector files. In the second example, a standard watermark pattern marked on a brass plate has been enriched with a microtext. The content of the text or 2D codes can be personalized dinamically using query from the customers database.

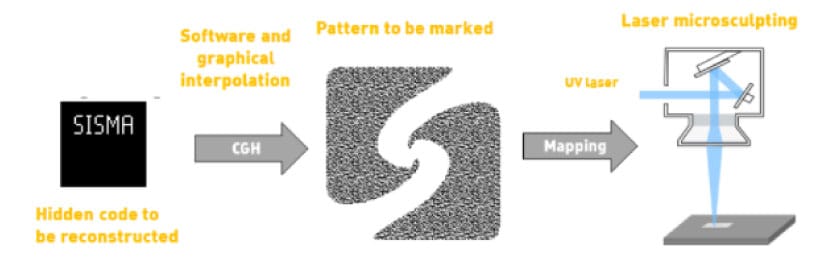

Laser marking of holographic features

We present a process that enables the generation of computer-generated hologram (CGH) patterns directly on the surface of metal products made of stainless steel, nickel, brass, gold, or a nickel-chromium (Inconel) alloy. The CGHs are designed by using an Iterative Fourier Transform Algorithm, and then are mapped onto the metal surface using UV nanosecond laser pulses. The laser-generated structures consist of optically-smooth surface deformations (craters and/or bumps), forming reflective diffractive optical elements (DOEs) capable of generating diffractive images in the far field.

The images can contain information about the marked products (e.g. serial number), providing their unique identification and traceability. Moreover, the holograms can contain additional security features, e.g. miniature signatures and identifiers invisible to the naked eye, and also can be embedded into standard marking patterns (e.g. QR codes). In this way, they can form aesthetic “steganographic” markings in which secret information is hidden inside an ordinary, easily-readable message.

Reference:

UIBM – Lotta alla contraffazione

https://uibm.mise.gov.it/index.php/it/lotta-alla-contraffazione

http://www.uibm.gov.it/attachments/no_to_fake_clothing.pdf

Foiling falsification with micromarks

https://www.lasersystemseurope.com/analysis-opinion/foiling-falsification-micromarks

Direct laser-writing of holographic markings for protecting luxury products against counterfeiting