Case study

Marking on dental implant elements and equipment

50W PICO laser

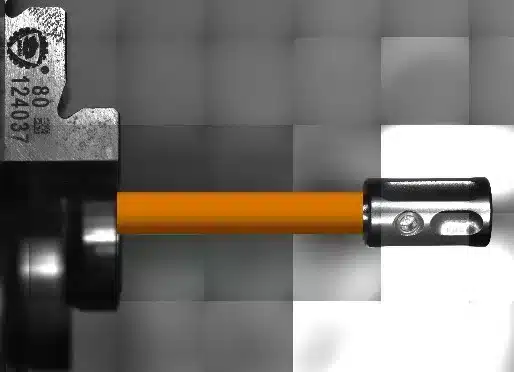

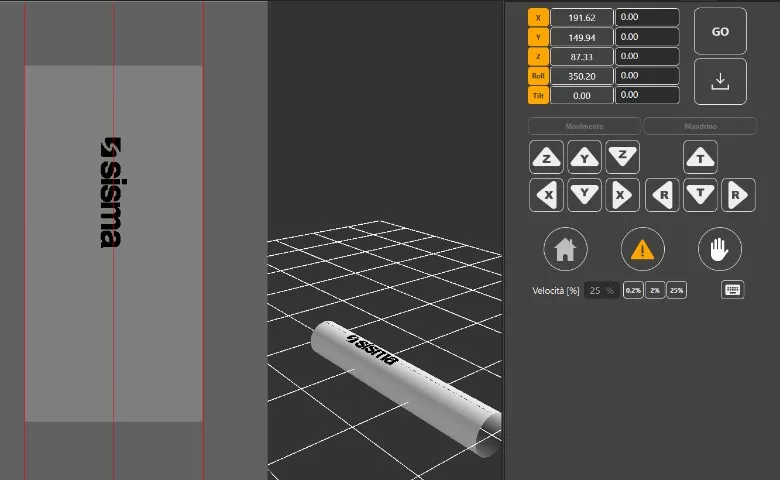

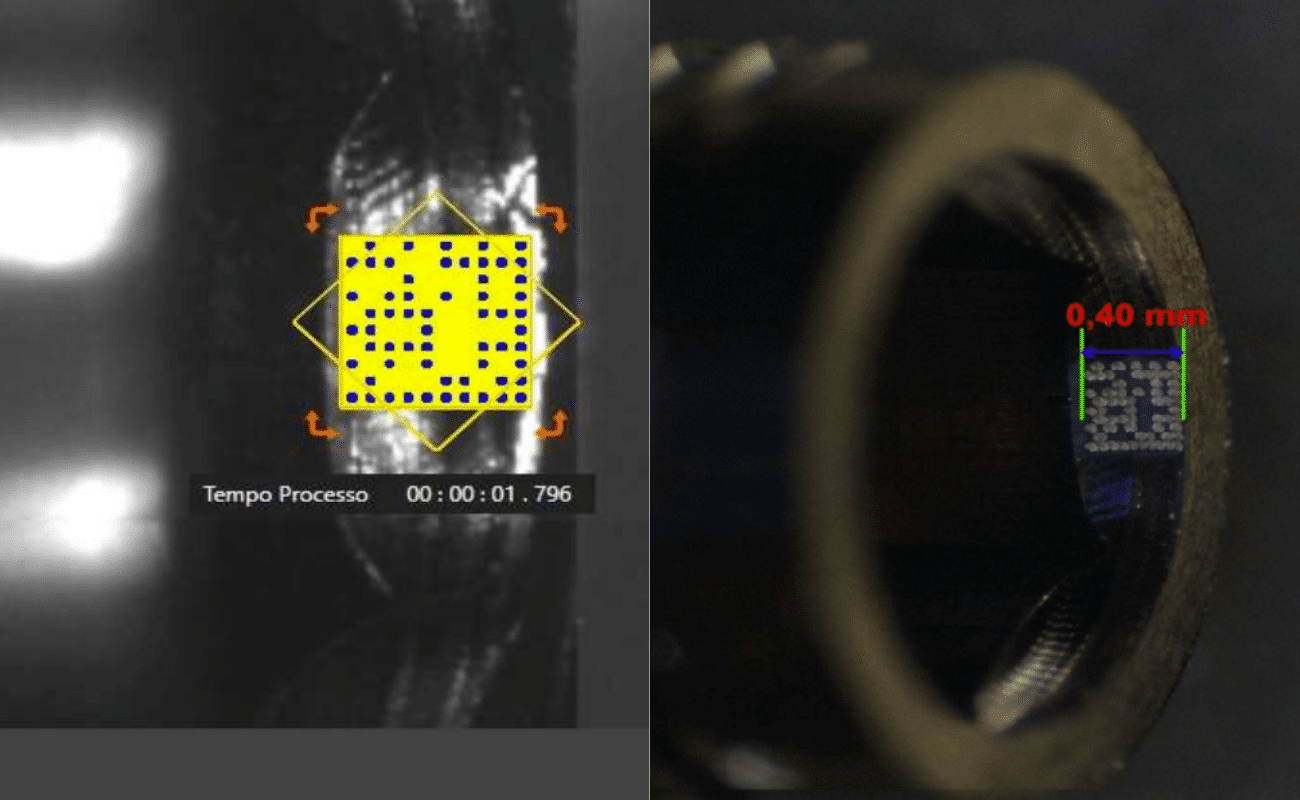

Trough the vision system, the area to be marked is determined (in orange)

The detected cylinder is unwound flat (grey rectangle on the left) showing the entire available marking area

Test with 50W Pico laser

As anticipated, similar tests to those done with the 20W MOPA were repeated with this other more powerful source and with ultra-short pulses, to verify its advantages and differences.

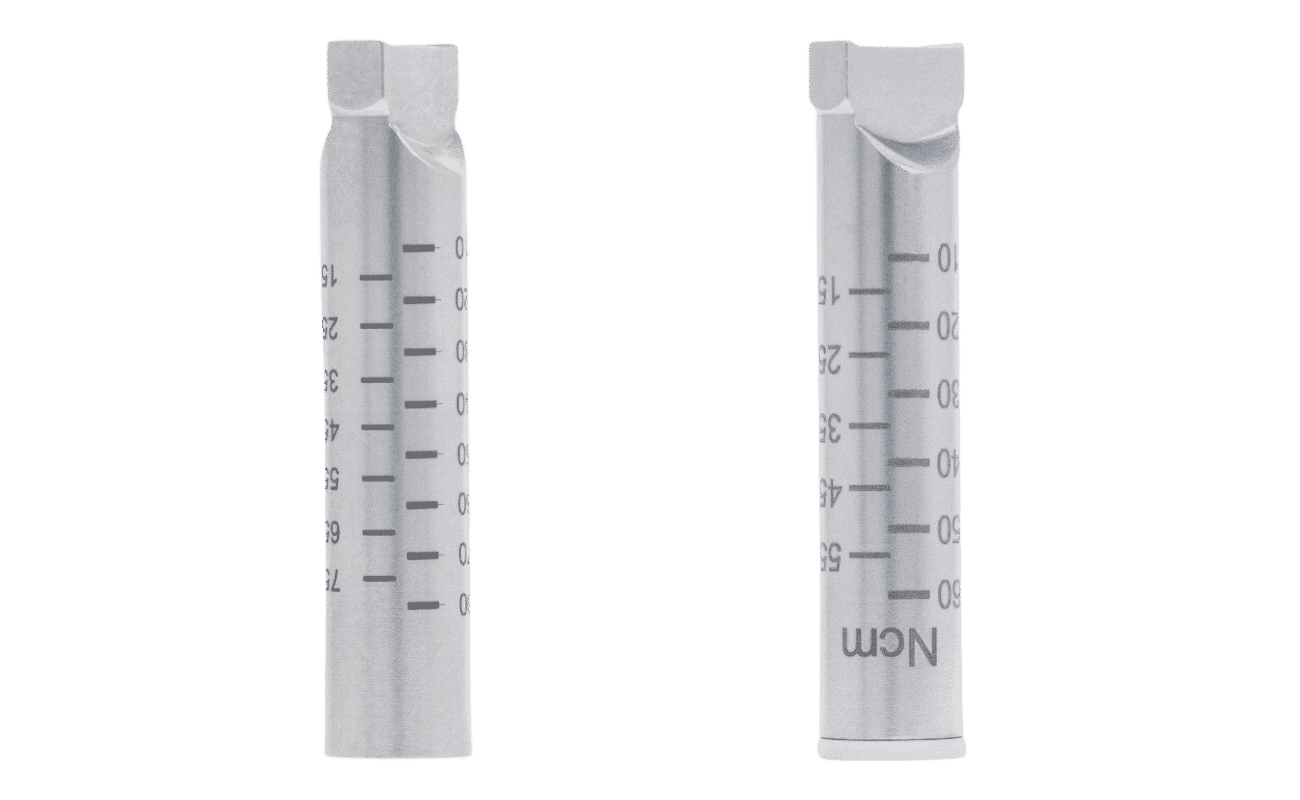

Stem with ring nut of the torque spanner. We have performed exactly the same process with significantly better results; in fact, with equal relevance to the touch, we obtained:

- Clearly more intense signs (blackening)

- Decreased working time: from 2 min e 55’’ to 1 min e 24’’

- More defined writings

Outer sleeve of the torque spanner. In this case, given the previous results, we decided to mark a graduated scale with smaller and denser digits. The results confirm the previous improvements.

The same goes for the Lanceolate Cutters.

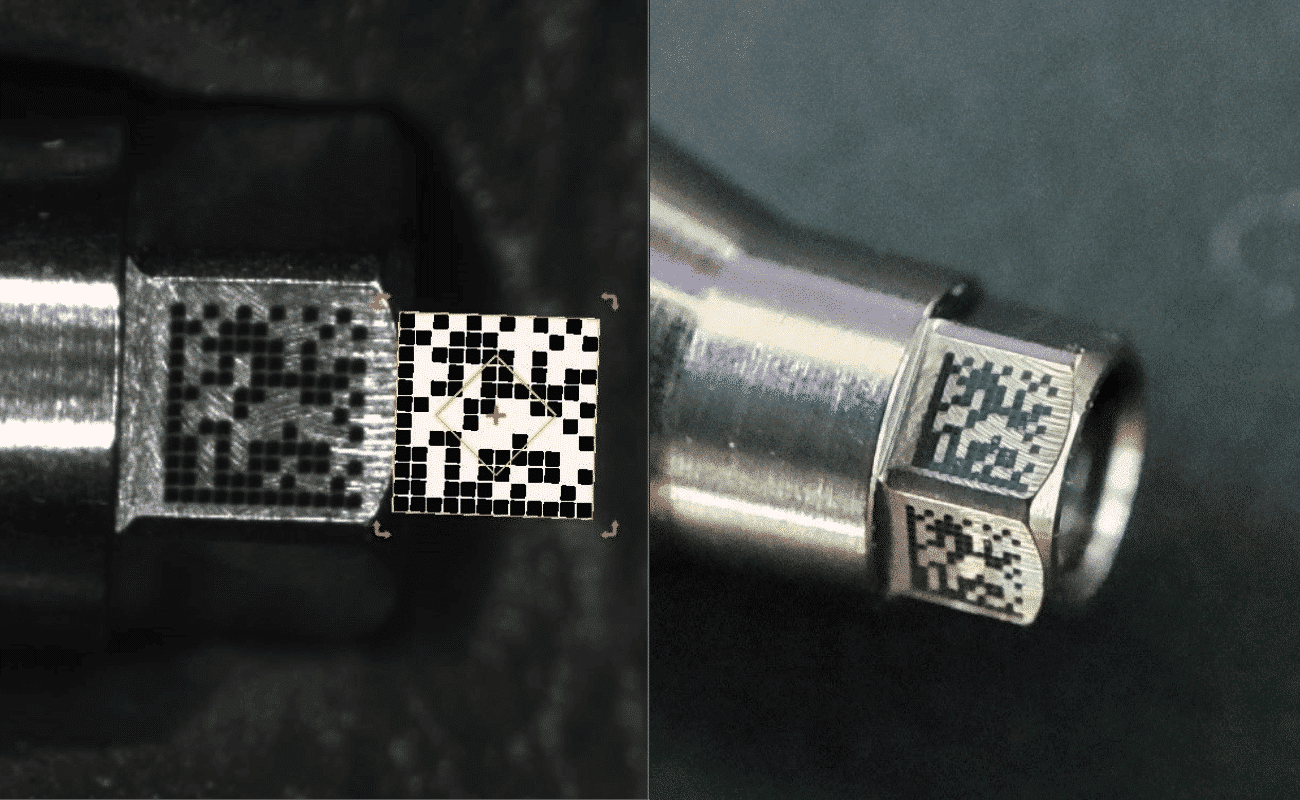

Very interesting was to check the differences in the datamatrix, which due to their size represent a fairly critical element.

Abutment. We repeated the same datamatrix, dimensions 1,16 x 1,16mm, format 12 x 12.

The difference in quality from the previous test is obvious. Of course, no problem with microscopic readability.

B&B Dental provided us with lance cutter, torque spanner, abutment and implant in order to develop a marking process. They are elements that must be resistant to corrosion and ensure long-term durability under stressful conditions such as decontamination and subsequent autoclave sterilisation.

It is important to achieve a marking with well-contrasted characters and marks, but not perceptible to the touch. We must therefore avoid removing too much material by carefully modulating the various parameters (power, laser speed, spindle speed, etc.).

The machine used in the tests is a BSP, equipped with a roto-tilting spindle. Marking tests on the various elements were first performed by equipping the machine with a 20W MOPA laser source; then the same, or similar, tests were repeated with a 50W Pico laser source.

Laser 20W Mopa and 50W Pico reults

Laser 50W Pico e 20W Mopa results

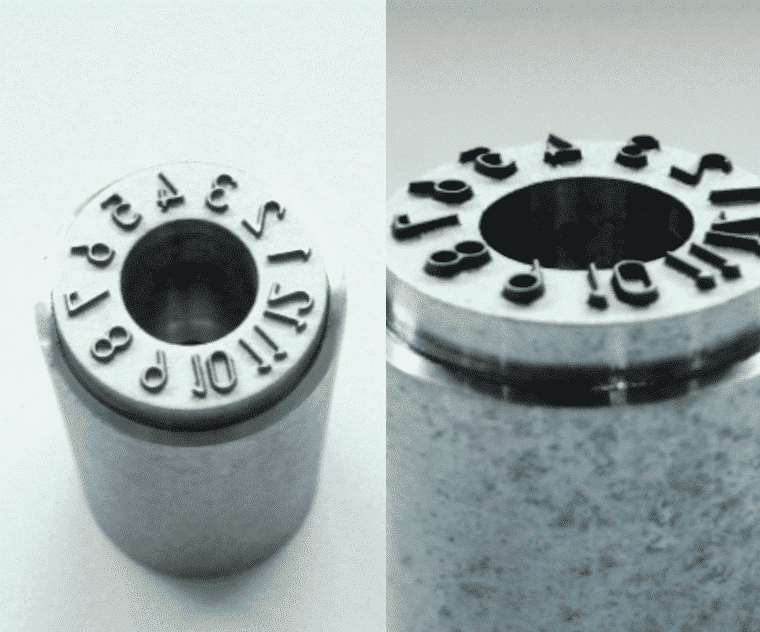

Datamatrix tests

Datamatrix and marking detail

BSP Pico

Implants. As mentioned earlier, the goal is to mark an extremely small datamatrix (0,4 x 0,4mm, format 10x10) inside a titanium implant screw, which is impossible with the 20W MOPA laser.

It is necessary to fix the implant, either with the mandrel or with appropriate casing, by tilting it so that the laser can mark in its inner part. The running time is about 10 sec. Reading through microscope is successful.

In conclusion, test results showed that the ideal laser for this type of processing is a Pico source. With the MOPA laser, with the exception of the 0.4 x 0.4 data matrix, all processes are feasible, but with a lower degree of blackening and detail and sometimes with significantly longer timescales.

The solution practiced here with a BSP Pico 50W, can be considered perfect given the results obtained.

This is a flexible, stable and accurate marking system, thanks to:

- granite bench

- 3 motorized axes

- precision motion axes of 50 microns

- axes stroke 300x300x300 mm

- roto-tilting spindle kit

- CVS vision system and Pattern matching software

Note that Sisma software systems also have full integration with the SQL database to retrieve and generate the UDI marking required by FDA and EU MDR regulations.

B&B Dental S.r.l. is a leading dental implant manufacturer in the field of oral implantology. It specializes in the design, manufacture and selling of dental implants and bone regeneration materials.

The company, based in San Pietro in Casale in the province of Bologna, was founded in 1992 from the surgical experience of Dr. Banzi. A scientific director and founder, he now coordinates a team of experienced dental engineers to develop new products and cutting-edge solutions to meet the growing clinical needs of its customers and their patients.

Curious about all the Sisma applications for marking and engraving? Contact us and we will be happy to answer all your questions.