Automotive

Laser welding in the automotive industry

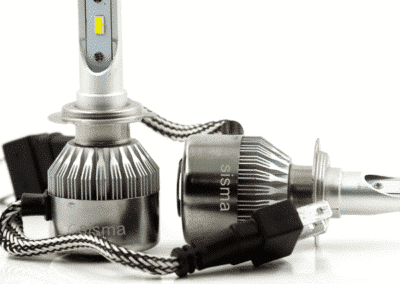

Laser welding is a technology commonly adopted by the automotive industry: it is used in many applications, both relating to structural components such as frames or doors and for all electromechanical or electronic components and related covers, including for example, airbag activators, windings in copper, to which is added the ever-increasing demand for e-mobility.

In particular, laser welding offers a guarantee in terms of functional and aesthetic quality, high productivity as well as reduced thermal invasion on the material: it essentially represents the ideal process both for onerous applications of structural components and for those applications in which precision and detail are functional to the creation of the component.

Not only advantages in terms of quality and productivity but also in terms of energy consumption. Laser welding, especially with fibre technology, is very efficient, managing to transform a large part of the input power into useful energy for the process.

Consumption is reduced, dimensions are compact, maintenance is minimal and the possibility of remote management of the process makes it very “Green”.

SWS, 3 or 4 axis CNC automatic laser welding station

SWS is the automatic CNC welding station with 3 or 4 interpolated axes controlled by CNC, with self-learning or ISO path. The axis movement system, with recirculating balls, guarantees high precision thanks also to the solidity of the structure and the materials used. In this case, the welding head follows a previously created tool path, moving in the work chamber depending on the size of the piece and the required equipment.

The laser source has been designed to guarantee high operating stability at both low and high power; the fibre technology allows to obtain a reduced size of the beam diameter combined with high stability, both in initial transients and for demanding uses.

The laser welding systems of the SWA range are specifically designed to carry out modification and repair operations on moulds damaged by wear or use

Laser systems find many applications in the mould sector and for the moulding processes of plastic or metal materials for the automotive industry. One of the most common uses in laser welding is that of the repair and maintenance of moulds by adding material: it is a semi-automatic process in which the operator’s skill is supported by very stable, repeatable technology and software functions that facilitate processing. Sisma offers a range of products dedicated to this type of process, from simpler and more compact models up to the SWA series which allows maximum flexibility and ease of use even on large moulds.

MODO with remote laser welding technology

The welding process is carried out with the aid of a galvanometric head; the motors that control the mirrors inside the scanning head move the laser beam within the perimeter circumscribed by the focal lens, with the advantage of process speed and ease of centring and programming.

Thanks to a rigid and modular structure, MODO weld guarantees high productivity while maintaining quality and repeatability of the welding process. The machine includes the CVS (Coaxial Vision System) vision system for viewing and easy centring of the piece which can be combined with the PM (Pattern Matching) software for automatic component recognition.

Laser marking in the automotive industry

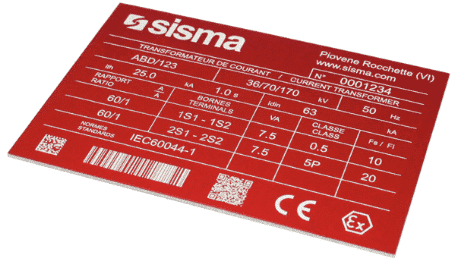

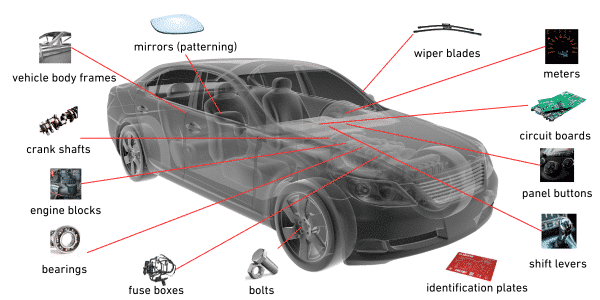

Laser marking of automotive components is a necessary process in order to guarantee the tracking and traceability of components throughout the entire production chain.

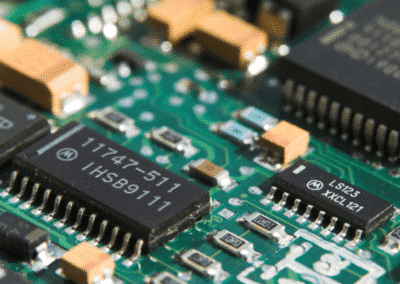

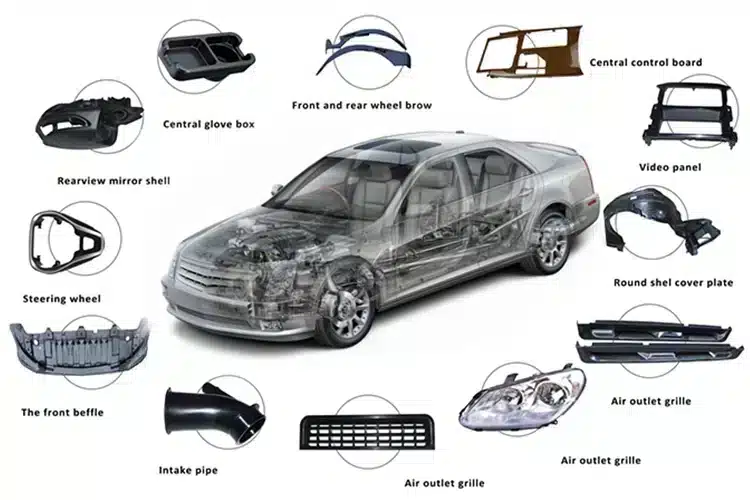

It is used to mark texts, logos, serial numbers, 1D or 2D barcodes and more, on a wide range of parts and materials, from engine parts to electronics with a high degree of precision and detail. But not only that, the products characterized by laser marking have details of the highest quality and definition, thus representing the most reliable, rapid, safe and flexible way to monitor and verify every single component production process.

In the automotive sector, marking is therefore of fundamental importance not only to have all the information relating to the vehicle available, but also to understand the steps involved in its creation.

Among the data generally marked, the name of the manufacturing company and the place and year of production are included in particular.

The parts that make up a car and require marking are many, but among them the chassis undoubtedly stands out, on which the vehicle identification number (VMI) is indicated which complies with the ISO 3779:2009 standard. The VIN is made up of three parts: the WMI for the car manufacturer, the VDS which indicates the car model and finally the VIS which refers to the factory and year of production.

Infrared laser: quality marking for metallic materials

Infrared laser sources allow you to create indelible and very defined markings on most metal and plastic materials. These are very versatile lasers, in compact sizes, which essentially require no maintenance but have important performances in terms of reliability, precision and repeatability.

They can be integrated within the entire range of solutions offered by Sisma, both in the configuration that can be integrated on assembly islands and in the closed version. The product range is very wide, both in terms of available laser powers, in terms of size of the pieces to be marked and in terms of automation. In fact, Sisma offers highly flexible and compact manual systems, multi-axis systems for multiple markings, systems that can be combined with automatic magazines, as well as with the possibility of integrating collaborative and/or anthropomorphic robots.

UV laser: high contrast marking on plastic and non-metallic materials

The laser marking process can be performed with different types of lasers, based on the materials and the yield that the marking itself requires. The UV laser sources, integrated into the MODO or Sart systems, are designed for all high contrast marking and processing applications where aesthetic/chromatic rendering, definition of the laser line and productivity are essential requirements.

This is not the usual damage-free laser marking. UV lasers excel above all in marking plastic, glass and other heat-sensitive materials: the peculiarity is that they have a shorter wavelength than the most common traditional lasers that operate in the infrared, which is advantageous because it ensures a reduced laser, minimal thermal impact and the possibility of carrying out very high definition processing on plastic and/or organic materials, even on very small surfaces.

Easy with MOPA laser source or Q Switch

Traceability is essential in the manufacturing industry and ensures that all products are fully monitored at every stage of the supply chain: The Easy desktop laser marker with MOPA source, a technology of great precision and speed, is ideal for the marking of codes, qrcodes and all those identifying elements essential for the supply chain.

The ability to adjust the pulse width indirectly influences peak power, allowing MOPA laser systems to mark on a wide range of materials with high-contrast results and vibrant colours on stainless steel.

SART, laser marking system equipped with a two-position rotary table

Sart is a laser marking system equipped with a two-position rotary table: the solution effectively responds to the demand for high productivity in the automotive sector, simultaneously guaranteeing maximum safety and the best ergonomics for the operator. The loading and unloading of the pieces takes place in masked time, on a table with a diameter of 700mm, with the protective partition that automatically raises and lowers, allowing high variability in the height of the pieces. Sart can be integrated with the dedicated robot interface, in order to guarantee all the functions necessary for the use of robotic automation systems, always safely.

Sart is modular and is available with infrared laser sources, from 20W to 100W power, CO2 and UV laser sources, capable of carrying out engraving, marking and micro-cutting processes on various materials. It is also compatible with the coaxial vision system (CVS), the Pattern Matching software and/or with the dynamic focus shifter function, for the creation of processes on complex non-flat surfaces.

Co2 laser the best solution for marking organic and coated materials

Laser systems with a CO2 source, such as the MODO, SART or SMARK series, are ideal for uniquely marking serial numbers, barcodes and QR codes on a wide range of organic materials, glass, plastic, painted surfaces, anodized aluminium.

Laser coding can take place directly on the piece or on a plastic or metal plate to then be applied to the element: tracing an element is fundamental in the automotive industry, where a component is often produced in one production line but assembled in another. It goes without saying that that element and the processes it has undergone must always be identifiable and traceable.

The CO2 laser sources proposed by Sisma are characterized by a very small laser spot, in the order of 0.1 mm, thus allowing high definition to be obtained. Then there is the possibility of using the CVS vision system for the automatic reconstruction of the working field and the pattern matching for the automatic positioning of the marking in the defined area.

OEM, laser marking on plastic and metal

OEM is the Sisma solution suitable for marking applications when integrations on automated lines and islands are required, thanks to the compact dimensions and the specifically developed hardware/software interface.

The OEM integrable laser source marks all types of metallic materials and most plastic materials with very high quality, thanks to the electric drawer for the generation and control of the necessary power.

The great flexibility of the installed software allows the creation and marking of various types of data, barcodes and data matrices to meet all traceability needs. The system can be integrated with CVS (Coaxial Vision System) and Pattern Matching software. Also in this case, various laser powers are available in the infrared range.