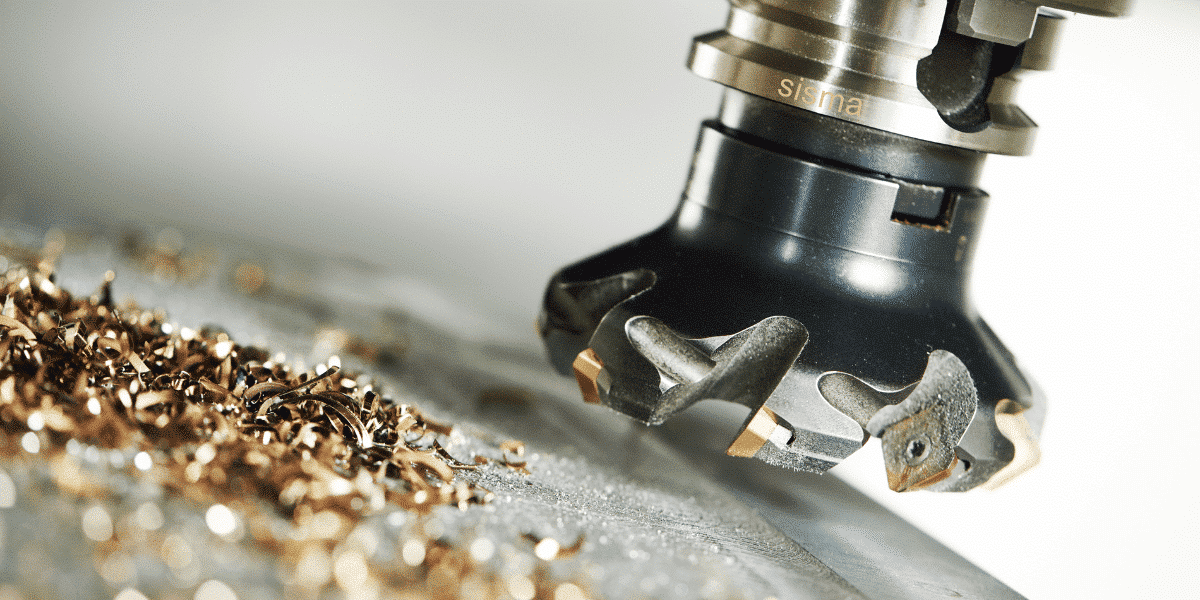

Mechanical processing

The mechanical processing sector has always represented one of the flagships of industrial production. This sector is characterized by very high standards of quality and precision, necessary to create essential products and components for various sectors, from tooling to heavy machining, from naval to automotive, from spare parts to rolling.

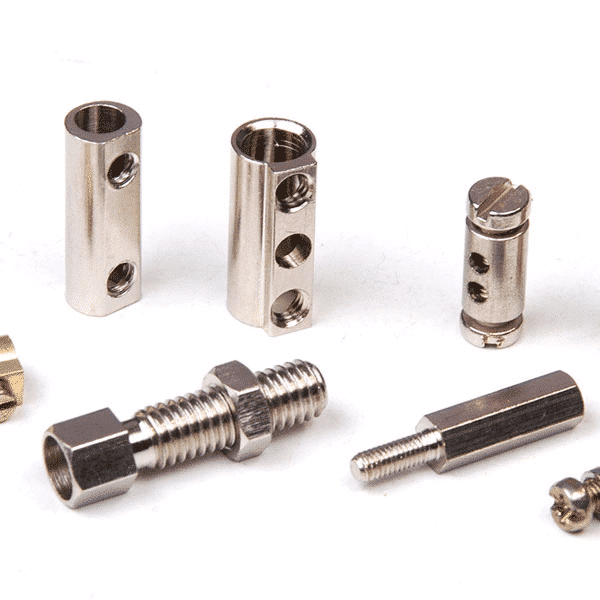

Mechanical processing refers to the manufacturing of metal components which takes place with the aid of appropriately programmed numerical control machinery. A large quantity of products derive from these processes: bushings, flanges, self-lubricants, gears, valves, joints…

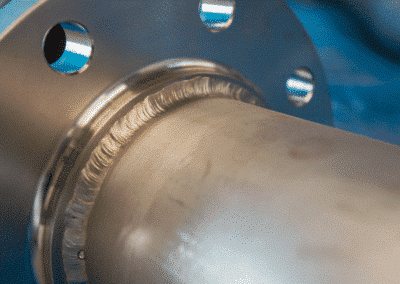

Laser welding in mechanical processing

Given its versatility, the laser is an excellent choice in all cases where it is necessary to carry out welding operations that require precision: this technology allows you to exploit the advantages deriving from a very small laser beam, from the possibility of modulating the process energy and the guarantee of obtaining a constant result.

Laser welding is particularly requested by many players in the automotive, medical, aerospace and electronics sectors, and is an ideal process for the mould sector.

MODO with remote laser welding technology

The welding process is carried out with the aid of a galvanometric head; the motors that control the mirrors inside the scanning head move the laser beam within the perimeter circumscribed by the focal lens, with the advantage of process speed and ease of centring and programming.

MODO weld, thanks to a rigid and modular structure, allows for high productivity while maintaining the quality of the welding process and repeatable results. The machine includes the CVS (Coaxial Vision System) vision system for viewing and easy centring of the piece which can be combined with the PM (Pattern Matching) software for automatic component recognition.

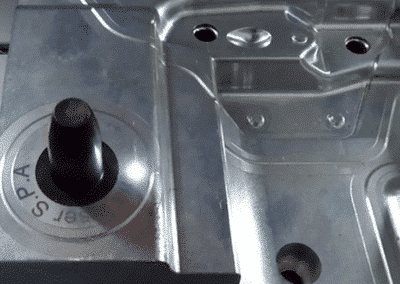

Infrared laser: quality marking for metallic materials

Infrared laser sources allow you to create indelible and very defined markings on most metal and plastic materials. These are very versatile lasers, in compact sizes, which essentially require no maintenance but have important performances in terms of reliability, precision and repeatability.

They can be integrated within the entire range of solutions offered by Sisma, both in the configuration that can be integrated on assembly islands and in the closed version. The product range is very wide, both in terms of available laser powers, in terms of size of the pieces to be marked and in terms of automation. In fact, Sisma offers highly flexible and compact manual systems, multi-axis systems for multiple markings, systems that can be combined with automatic magazines, as well as with the possibility of integrating collaborative and/or anthropomorphic robots.

Among these, the LWS-A system stands out, a compact laser marking station that allows for a large load, thanks to the 3-axis gantry movement of the laser, which allows the positioning and marking of large quantities of pieces or multiple markings on a single large piece.

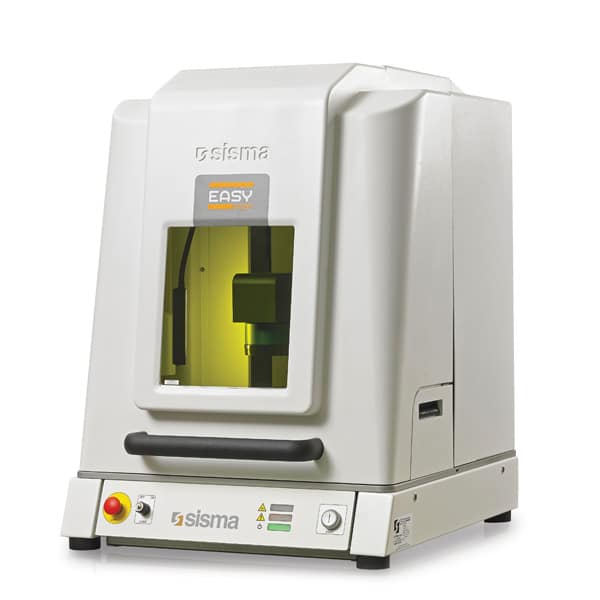

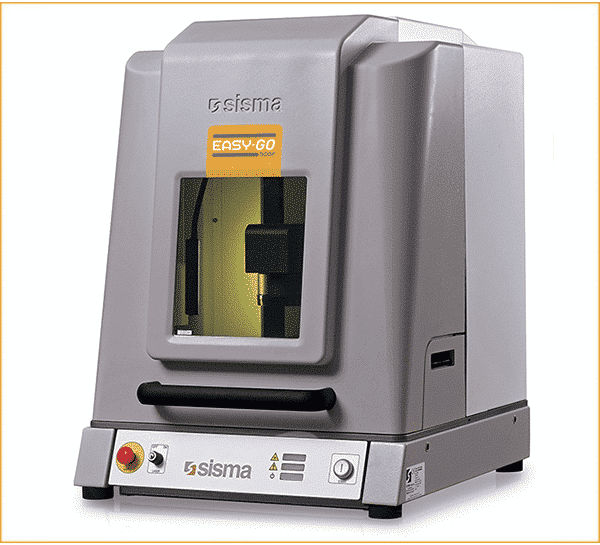

Easy with MOPA laser source or Q Switch

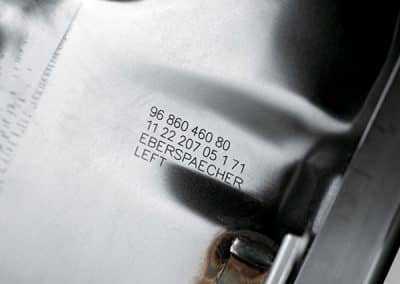

Traceability is essential in the manufacturing industry and ensures that all products are fully monitored at every stage of the supply chain: The Easy desktop laser marker with MOPA source, a technology of great precision and speed, is ideal for the marking of codes, qrcodes and all those identifying elements essential for the supply chain.

The ability to adjust the pulse width indirectly influences peak power, allowing MOPA laser systems to mark on a wide range of materials with high-contrast results and vibrant colours on stainless steel.

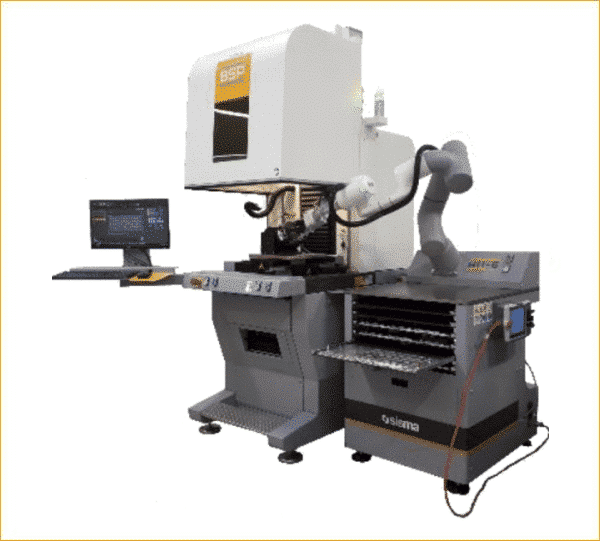

BSP+WH-6P Cbot

To respond to the need to automate mechanical operations within production, Sisma has developed a robotic system that allows repetitive product loading and unloading operations to be automated. The WH-6P CBot automatic warehouse is the perfect synthesis between a collaborative robot and a drawer warehouse system: it is composed of a static storage section with 6 removable and interchangeable pallets and a robotic arm, which extracts the pallet from the magazine and collects the contents of the tray by placing it on the marking area. The system is designed to work side by side with people without the need for cumbersome safety nets.

Marking lasers for the mechanical processing sector

The greater automation of processes such as, for example, counting the pieces produced by reading codes printed on the component, can be fundamental to achieving production optimization.

Therefore, equipping themselves with a laser tool for marking allows companies to save time, to always obtain impeccable results and to see their efficiency grow as a result, because the activities are completed quickly and automatically, limiting the need for intervention by the operator.

Marking can be applied with extreme precision and aesthetic rendering on different geometries by easily engraving barcodes or qrcodes, logos, serial numbers and so on.

SART, laser marking and engraving system with rotary table

Sart is a laser marking system equipped with a two-position rotary table: the solution effectively responds to the demand for high productivity in the automotive sector, simultaneously guaranteeing maximum safety and the best ergonomics for the operator. The loading and unloading of the pieces takes place in masked time, on a table with a diameter of 700mm, with the protective partition that automatically raises and lowers, allowing high variability in the height of the pieces. Sart can be integrated with the dedicated robot interface, in order to guarantee all the functions necessary for the use of robotic automation systems, always safely.

Sart is modular and is available with infrared laser sources, from 20 to 100W power, CO2 and UV laser sources, capable of carrying out engraving, marking and micro-cutting processes on various materials. It is also compatible with the coaxial vision system (CVS), the Pattern Matching software and/or with the dynamic focus shifter function, for the creation of processes on complex non-flat surfaces.

Big Smark, laser marking and engraving system with base

The advanced features of the Big Smark laser source allow you to carry out engraving, marking and cutting processes in line with the highest technical standards.

Big Smark can be integrated with all SISMA accessories as well as the coaxial vision system (CVS) and Pattern Matching software. It has a practical working chamber of 500 mm x 500 mm (maximum height of the piece 530 mm with F100 focal length) with easy access thanks to the opening on three sides.

The machine’s software, developed internally by SISMA, is the ideal solution for managing files and defining parameters, even in the case of complex processes.