RFX: il più grande esperimento al mondo per lo studio del confinamento dei plasmi da fusione nucleare.

SISMA collabora al progetto MIAIVO – Meccanica Innovativa e Additiva Integrata: il VenetO dalla ricerca alle opportunità nel mercato attuale e futuro – per analizzare la fattibilità tecnologica di un insieme di modifiche alla macchina sperimentale RFX-mod2.

Nel 2018 siamo entrati a far parte del progetto MIAIVO, il cui scopo è analizzare la fattibilità di un insieme di modifiche alla macchina sperimentale RFXmod2, sviluppando tecnologie e processi innovativi quali ad esempio: manifattura additiva metallica; sigillatura di contenitori da vuoto con combinazione di metalli e tecnopolimeri, isolamento elettrico di componenti da vuoto mediante trattamenti superficiali. Il progetto MIAIVO rappresenta un eccellente banco di prova per la realizzazione del prototipo di iniettore di neutri da 16 MW e 1 MV nell’ambito del progetto di reattore per la fusione nucleare ITER.

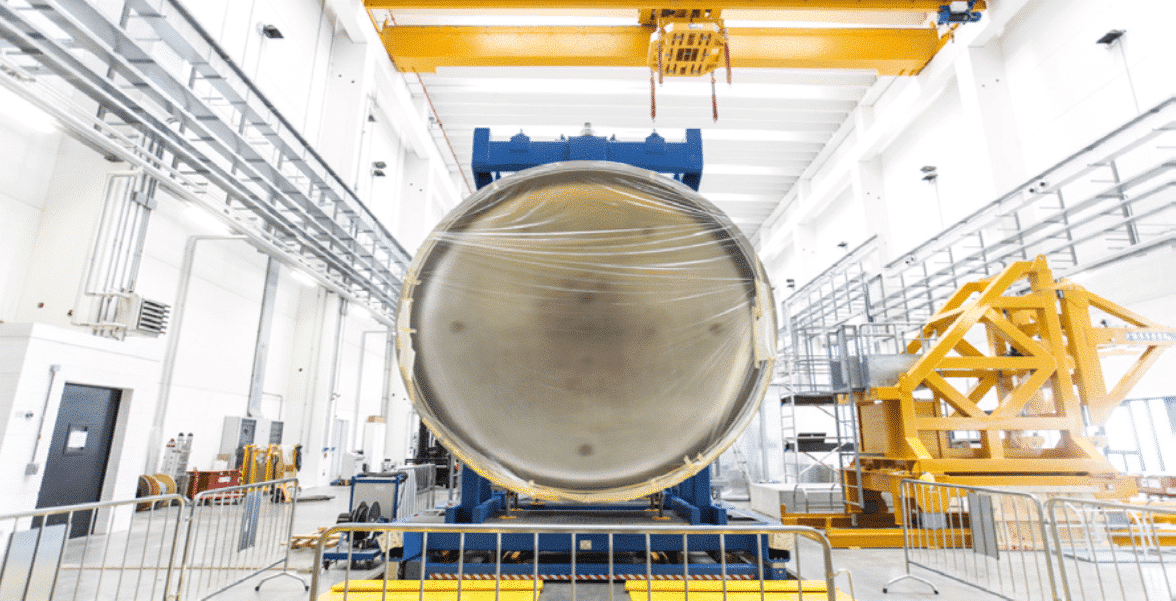

Figura 1: RFX-mod2.

Figura 2: RFX-mod2.

RFX è il più grande esperimento al mondo per lo studio del confinamento dei plasmi da fusione nucleare in configurazione Reversed Field Pinch; RFX-mod2 nasce dalla necessità di migliorare il controllo delle instabilità del plasma. È in questo contesto che si inseriscono le nostre competenze (oltre a quelle delle altre due aziende partecipanti Alca Technology S.r.l., Zanon Pressure Equipment S.r.l.) per la produzione di componenti innovativi di natura non convenzionale attraverso processi di “additive manufacturing” nel campo della micromeccanica, con l’adozione di soluzioni innovative nella costruzione di componentistica meccanica di precisone, adottando criteri di risparmio, di efficienza energetica e di minimizzazione dell’impatto ambientale attraverso processi a bassa produzione di scorie.

Siamo impegnati in questo senso, sfruttando le nostre stampanti 3D a fusione laser selettiva di letto di polvere metallica MYSINT 100 e MYSINT 300, nella progettazione e produzione di componenti in acciaio Inox 316L, creati in un unico processo senza fasi intermedie, oltre a componenti in rame e leghe di rame.

Figura 3: MYSINT 300 e i pezzi realizzati in acciaio Inox 316L.

Figura 4: MYSINT 100 e i pezzi realizzati in lega di rame.

Il progetto Meccanica Innovativa e Additiva Integrata: il VenetO dalla ricerca alle opportunità nel mercato attuale e futuro, è finanziato dalla Regione Veneto con il fondo POR FESR 2014-2020.

- Fondazione Centro Produttività Veneto (CPV) – Vicenza: Coordinatore del progetto;

- Consorzio RFX – Padova: Laboratorio di ricerca scientifica e tecnologica; studia a livello teorico le modifiche da apportare alla macchina RFX-mod2;

- Zanon Pressure Equipment S.r.l. – Schio: Ha il compito di convertire l’attuale struttura di supporto di RFX-mod2 nella camera a vuoto che ospiterà l’esperimento;

- Alca Technology S.r.l. – Schio: Ha il compito di studiare il processo di rivestimento di allumina della parte interna della macchina RFX-mod2 con la tecnica di «Magnetron Sputtering»;

- SISMA S.p.A. – Piovene Rocchette: Ha il compito di studiare e sviluppare i componenti in acciaio speciale e in rame della macchina RFX-mod2 mediante «Additive Manufacturing»

- Spesa totale € 4.276.600,00, Contributo totale € 2.040.540,00