Case study

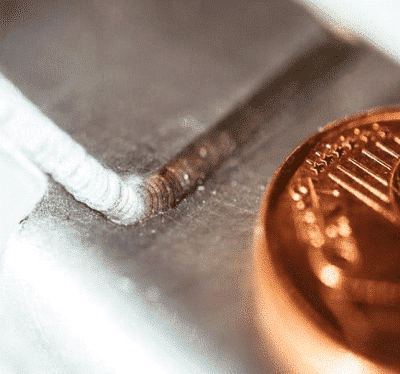

Laser welding solutions for mold reparations, mold maitenance and micro-welding

Meccanica Tecnica s.r.l., is a leader company in precison mechanical engineering. The company offers contractor service, so the goal was getting welders capable of meeting a variety of market demands, such as:

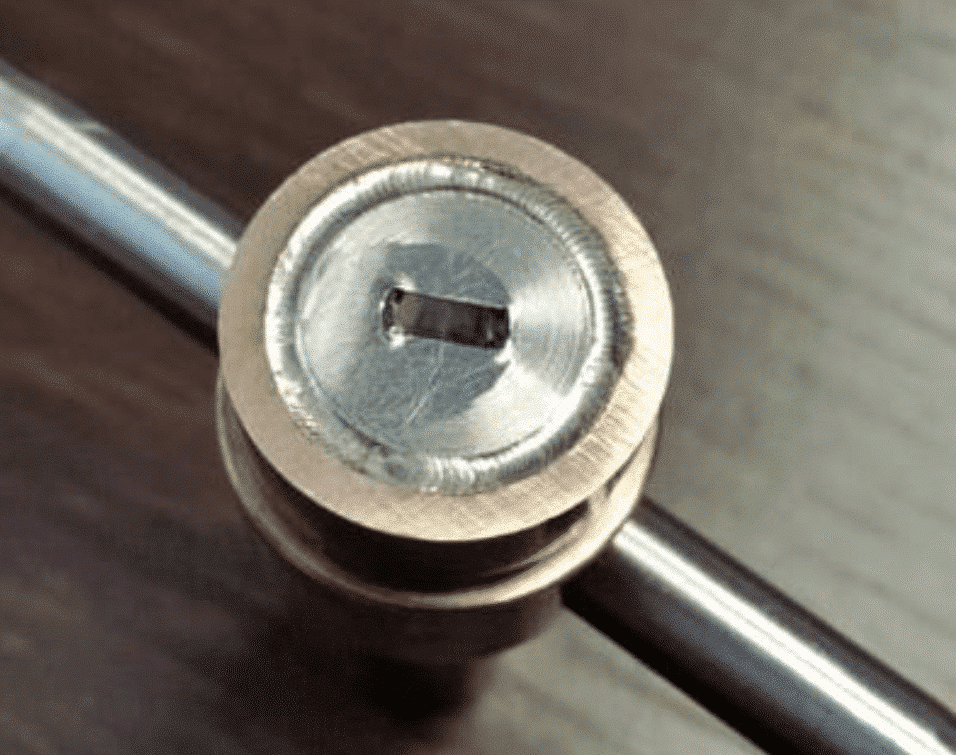

• repair molds, bearings, shafts, valve seats and turbine blades

• weld various kind of materials (steel, alloys, aluminium, titanium, cast iron)

• cover as wide renge as possible in terms of weight and size of workable objects

• weld extremely small parts

The only technology that can address all these needs is laser welding, which is successful in many situations because of some of its specific features:

-

Insignificant heat input during the deposition of fill material

-

minimal deformation of parts and minimal metallurgical damage

-

high strength and very high speed

-

welding rod very small (few tenths) if needed

-

solderability of many materials like steel (even hardeness up to 60 HRC), alluminium, alloys of bronze and copper, titanium

-

solderability of materials different from each other (e.g. steel and copper)

-

reduced cost per weld in high-volume applications.

Versatility is one of the strengths of Sisma laser welders, which in fact enable them to:

• easily reach particularly difficult places such as grooves or deep holes and working on complex areas such as edges, corners…

• create software-programmed welding paths, following customer-determined profiles and/or paths of regular shapes…

After a careful analysis of requirements and through close discussion with Sisma engineers,

Meccanica Tecnica opted for two laser welders capable of covering almost all the required cases:

• SWA 450F with fiber laser, ideal for mold reparation

• SWT with fiber laser, excellent for micro-welding

The fiber laser has important advantages over a lamp laser:

• no maintenace

• smaller spot, important in edges and for micro-welding

• more power, so higher speed.

SWA Fiber, key features:

• wheeled machine, easy to move to on-site for non-transportable parts

• large telescopic and rotating arm to reach distant and/or awkward points

• optical unit sliding in X and adjustable

• advanced software with tracked routes

SWT Fiber, key features:

• stability and robustness (ability to load up to 120Kg) with 3 axis machine

• ideal for detailed and precise machining

• possibility of working for small series

• ergonomy

• optimized software to ensure process repeatability

• loading of welding recipes, remote diagnostics

Curious about all Sisma applications for welding? Contact us, we will be happy to answer any questions you may have.