news

Fill – It

A proprietary texturing software package SLC3 is the SISMA software controller able to perform full control of laser machines, integrating visual interface and CAD features.Sisma has introduced in the SLC3 a proprietary texturing software package for...

OPEN DAYS SISMA 16 -17 -18 -19 May 2023

Open Days Sisma 2023! In this occasion you will have the opportunity to see and test all the machines produced by us like marking sources, welding and cutting lasers. Kindness, courtesy, professionalism, technology and vision will be, along with your presence, the...

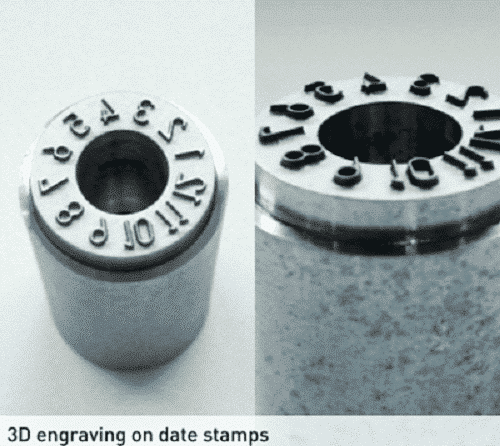

Easy mold

Modular solutions for 2D-3D laser engraving and texturing Find out how SISMA made it easier for people to create laser engravings and textures on punches, electrodes and other applications that require 2D-3D texture laser processes. ENGRAVING PROCESSES *Dynamic Focus...

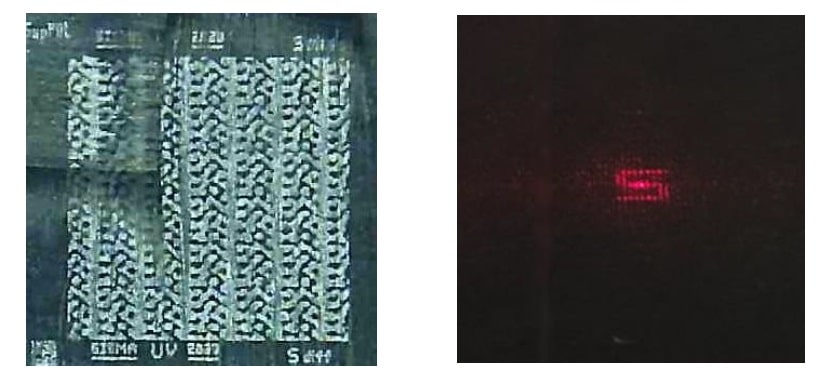

Laser Fabrication of Holograms on Carbon Fiber Reinforced Polymers

The University of Patras, in collaboration with SISMA, has presented a new research work at the Conference on Lasers and Electro-Optics (CLEO) 2022. In this work, holographic optical elements (HOE) are fabricated on the surface of mirror-polished Carbon Fiber...

SISMA sells its 45% of share capital of the JV with TRUMPF, while maintaining exclusivity in the LMF Jewellery and Fashion market.

Piovene Rocchette, 29.12.2021 SISMA sells its 45% of share capital of the JV with TRUMPF, while maintaining exclusivity in the LMF Jewellery and Fashion market. The “closing” of the transaction here below happened on December 29th, 2021 as it was planned,...

SISMA sells its investment in the JV with TRUMPF regarding metal 3D printing.

Piovene Rocchette, 11.11.2021 SISMA sells its investment in the JV with TRUMPF regarding metal 3D printing. Piovene Rocchette (VI), 10 November 2021 - Following prior SISMA S.p.A. press releases that announced its intention to leave to TRUMPF GmbH the LMF Business,...

DYNAMIC FOCUS SHIFTER (DFS)

DYNAMIC FOCUS SHIFTER (DFS) The secret ingredient of how laser markers work on non-planar surfaces.The Dynamic Focus Shifter bases its functionality on the presence of a third optical axis which, by moving the lens within the optical path, varies the size...

3D Printing for Eyewear

Additive manufacturing technologies will shape the future of fashion and eyewear manufacturing enabling faster prototyping and short scale production of customized goods. In Sisma we developed 3d printing technologies for powder metal and uv cured...

Anti Counterfeit features for luxury goods

Anti Counterfeit features for luxury goodsCounterfeit fashion products are costing in terms of brand reputation and revenues: laser marking technology could be the answer.The Italian Patents and Trademark Office estimates that in the eyewear industry...

SWA, laser welding and mold maintenance system with fiber source.

SWA, laser welding and mold maintenance system with fiber source.SISMA has decided to take an important step in the world of molds, presenting a new product to expand the current range, an absolute novelty and available on the market as early as May...