A proprietary texturing software package

SLC3 is the SISMA software controller able to perform full control of laser machines, integrating visual interface and CAD features.

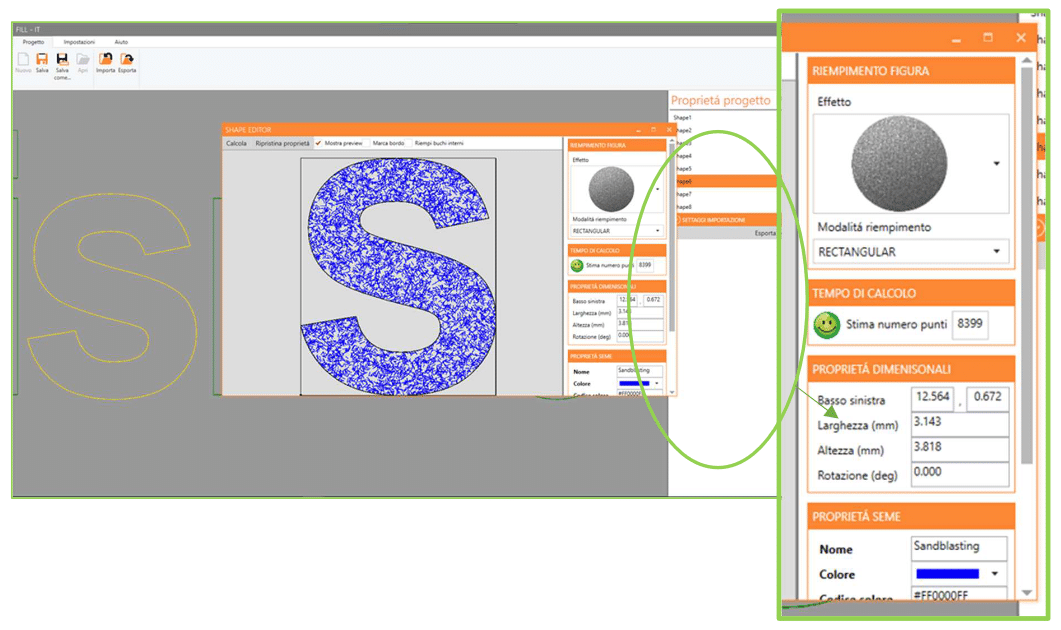

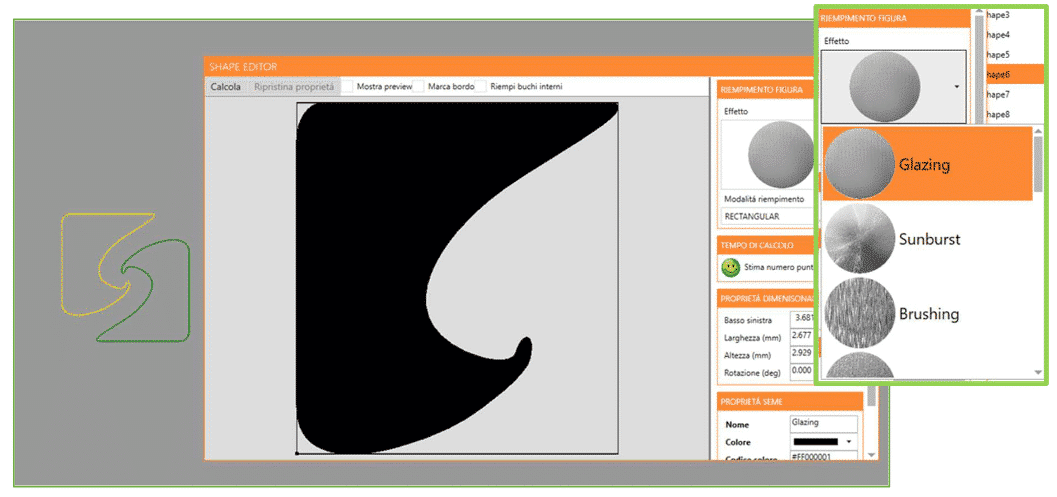

Sisma has introduced in the SLC3 a proprietary texturing software package for metal and/or sunglass and prescription lenses, called FILL IT, which allows simple but selective vector textures such as sandblasting, brushing, perlage, radial or axial (Còtes de Genève) grinding, and geometric finishes that cannot be achieved with traditional machining.

Laser marking is extremely effective on metals, where it is easy to achieve a wide range of diverse results. Laser marking, as well as laser engraving, is clean and precise.

It can be used to easily create 2D textures and 3D engravings to enhance or customize fashion products.

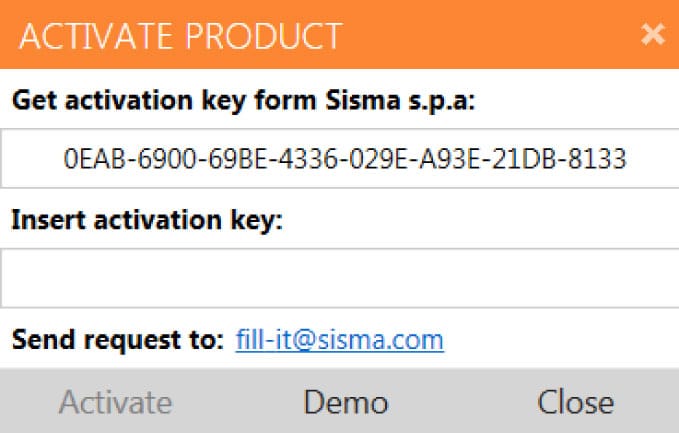

The FILL IT feature can be acquired separately and licensed on our marking systems equipped with the newest SLC3 control software.

The software package can fill up defined regions with vector surface effects to simulate different frosting effects like glazing, brushing, sandblasting and create geometrical and decorative features. Most of the effects can be performed in a tiled, radial or circular fashion (e.g. in brushing).

The different processes are achieved by moving the laser over the surface with specific trajectories, according to established patterns that return a certain texture or a particular effect. Various types of metal (copper, brass, etc.) can be used, but the best results are obtained with steel, preferably polished to a mirror finish.

For this kind of processing, it is worth using a MOPA laser, not too powerful; ideally a 20w MOPA, which we find, for example, on BIG SMARK and MODO.